“We usually find gas in new places with old ideas. Sometimes, also, we find gas in an old place with a new idea, but we seldom find much gas in an old place with an old idea. Several times in the past we have thought that we were running out of gas, whereas actually we were only running out of ideas.” - Adapted from Parke A. Dickey by American Potential Gas Committee

(* = First Star portfolio company)

Most everything we rely on to sustain our society – adobe walls to steel skyscrapers, crude oil to uranium, stone tablets to silicon wafers – got its origins in the subsurface, the earth beneath our feet (think, everything bedrock and below). And now, as the world wrenches itself into the start of a massive, extended, painful energy transition, I believe the subsurface will save us yet again – and drive massive returns for investors in the meantime.

At First Star our core thesis is that “the evolutionary edge of computing” is transforming every industry. Compute, automation, sensing, simulation, AI/ML are making it feasible to achieve venture-scale gross margins (60%+) and returns in products and markets that previously looked impenetrable to tech startups. The unstoppable forces of capitalism and compute are driving rapid advances in seeing and operating underground - mapping/modeling the subsurface, automating equipment and job site activities, improving heat transfer and materials extraction, and applications previously farfetched.

Cost and time-to-commercialization curves continue to fall swiftly due to: shorter prototyping/iteration cycles (and deployment schedules); better-characterized risk around subsurface resources and project outcomes; complementary technological advancements across fields from materials science to petroleum engineering and beyond. Additionally - like how space/orbital tech has seen a decade-long funding boom largely driven by rapidly falling launch costs, subsurface startups are even better-poised to benefit from decades of continuous subsurface, drilling, sensing, fracking and other improvements driven by the oil and gas industry.

New computing technologies making it cheaper/easier/faster to characterize and operate in the subsurface leads to lower cost of capital for startups and improved ROI for investors (risk capital and project finance alike). This unlocks bigger, more sophisticated downstream capital across debt, equity, project and equipment finance, etc. The subsurface will save us, and it is ripe for the nexus of startups and VC to capitalize – we just need to keep digging.

Metals, Mining, Hydrogen

Metals and rare-earth elements power our modern world, and become even more critical as we transition to clean energy. Novel approaches to resource discovery have made exploration less invasive, capital-intensive and risky. Companies like KoBold Metals, EarthAI and others are using new combinations of sensing platforms and compute models to de-mystify where minerals lie below. Extraction technologies are improving, too, to become more efficient and less emissive. For example, copper leach heap mining – in which massive heaps of crushed rock containing copper ore are flattened over huge areas, then irrigated from above with a leaching agent that reacts with the ore, drawing a copper-rich solution from the rocks into a collection pool below – can be made far higher-yield and more efficient by using in-heap sensors to better target copper in the heaps. Some techniques use muon sensors, which detect high-energy fundamental particles (called muons) as they pass through earth via cosmic rays. Muon behavior can be used to build geophysical models to visualize and target optimal areas inside leach heaps to boost yield by up to 20%. A current ARPA-E project seeks to mine minerals by injecting a reservoir with supercritical CO2 fluid, binding minerals to the fluid, then extracting it. Crazy Ideas That Might Actually Work are in no short supply.

Above: subsurface-penetrating muons sent from the sun to help us love metals better (also my favorite image I’ve ever seen in a pitch deck)

Improved metals refining technologies abound, too. The age of compute-enabled electrochemistry is upon us. Phoenix Tailings uses a highly-efficient, zero-waste electrochemical process to pull magnets, rare-earths and other high-value metals out of mine tailings that would otherwise sit in a tailings pond as dangerous, toxic waste. Other startups are using tailings ponds and other mine waste to cheaply sequester CO2. Magrathea Metals is using electrochemistry to make magnesium (2/3 the weight of aluminum and 3-4x lighter than steel) from seawater brine, a lost industrial art that could prove critical to lightweighting the energy transition. As forces economic and political pull industry and manufacturing back to the US, continued advances in materials and electrochemistry will enable ever-cleaner ways of sourcing and refining the metals we need.

Geologic hydrogen - sometimes called “white hydrogen” - is a newer area of focus but could be huge for solving economical, truly clean hydrogen supply at scale. The relative immaturity of the approach brings its own risks, but DOE recently announced $20m in funding for “cracking hydrocarbons in the subsurface” and the race is on to discover and extract these resources. No need to mess with intermittency or matching concerns - just pull the H2 out of the ground where it’s hanging out. I have my own worries about the hydrogen market and associated incentives more broadly. But if we are, indeed, heading toward a hydrogen future (and energy majors are trying very hard to make sure that’s the case) then I’m hopeful for this approach over most others.

Geothermal

The subsurface also contains truly massive amounts of clean, firm power. Geothermal energy (sourced from hot, juicy rocks far below), whose heat we capture and use to generate electricity, is available 24/7 and will be a key piece of the energy transition. Zanskar* uses a vast array of data, sensors and geophysical expertise to build AI models that characterize the subsurface in high resolution and with great accuracy. Heat discovery is the bottleneck for geothermal power. In making grid-scale geothermal energy resources eminently cheaper and easier to discover and drill, they will unlock clean, firm power for the grid by giving developers and investors a far more attractive risk/return profile. Zanskar can use proven geothermal drills, fracking techniques and power plant designs to develop the heat resources they discover. To further accelerate ongoing tech transfer, DOE’s Geothermal Technology Office has brought together a consortium (including the Society of Petroleum Engineers International) to create the Geothermal Energy from Oil and gas Demonstrated Engineering (GEODE) initiative “to leverage best practices from the oil and gas industry to increase geothermal development.” Improved turbine designs and heat transfer technologies are also contributing to more efficient extraction of subsurface heat from these wells, which are largely conventional hydrothermal resources (i.e. an existing reservoir of hot water under caprock).

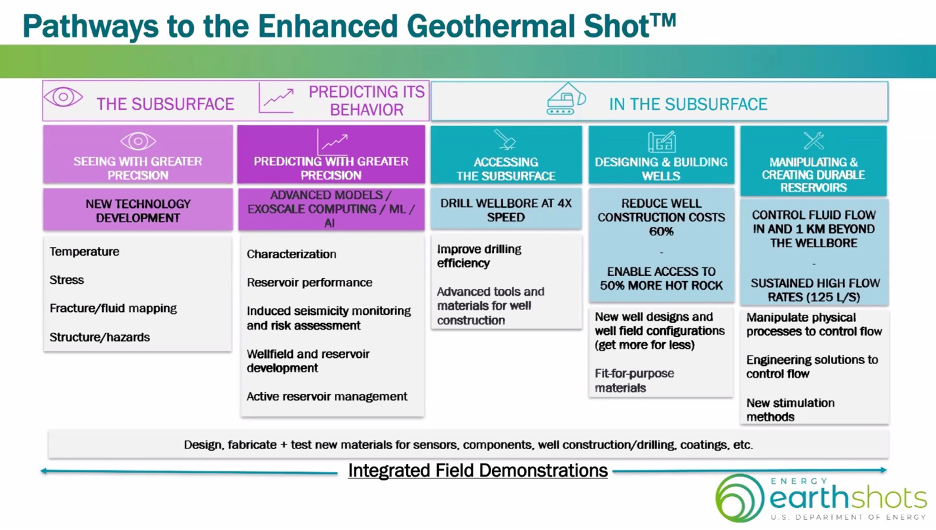

Companies building for Enhanced Geothermal Systems (EGS), on the other hand, are creating their own reservoirs in the hopes of avoiding the resource discovery bottleneck as much as possible. These companies are pioneering new drilling approaches, reservoir creation and design techniques to get deeper and hotter than ever. Fervo’s directional drilling approach recently led to a first-ever result in proving that EGS approaches can actually work in the field, a massive milestone for the sector. Quaise’s plasma drill (though facing R&D headwinds) and Eavor’s layered/looped reservoirs also offer hope for accessing geothermal energy across a much broader set of geographies and geologies. What two tailwinds do they all have in common? First, O&G tech has made it possible to instrument and control drills that work even in the hot, corrosive deep subsurface. This BCG report likens geothermal’s current situation to the shale revolution: “Geothermal is potentially at an inflection point similar to the oil & gas industry in 2008, when new technologies radically changed the landscape.” Second, computing is accelerating progress across the field. Consider these two slides from the DOE’s recent EGS Earthshot review:

Above: sensors, data, compute - loop it.

Direct use geothermal also holds immense promise for heating and cooling buildings and homes at half the cost (or less!) of natural gas, and with a tiny fraction of the emissions. Buildings are a notoriously heavy-emitting, tough-to-decarbonize sector, and HVAC for large buildings drives 25% of all new power demand in the US. Bedrock Energy* is automating and modularizing the process of drilling geothermal HVAC wells for large buildings. To do so they must access several thousand feet of depth, often in densely populated areas. They achieve this by designing, instrumenting and controlling a variant on an existing drill type to run it faster, more accurately and with minimal human involvement.

They can even make it easier to decarbonize HVAC for entire neighborhoods and cities at once by making it far cheaper to drill wells for district heating, a highly efficient system wherein a network of geothermal HVAC wells runs to individual structures but is pumped by a central source. A project in Framingham, MA recently broke ground on a utility-funded networked geothermal system that will provide heating and cooling to 30+ homes and buildings from a single shared ground source. Here’s a good overview of how quickly the movement is gaining steam, with fast-follower projects springing up across the country. Startups like DIG Energy (also developing their own drills) and Dandelion Energy (using existing water well-drilling trucks) are drilling shallower wells for single-family home HVAC.

Tunnels and Transmission

Horizontal tunnels of all diameters are becoming more critical everywhere. If you ask me the highest calling for The Boring Company, it’s decarbonizing urban mobility by rapidly building new mass public transit tunnels in dense areas. Undergrounding electrical transmission is a hot topic, too, as permitting fights and jurisdictional uncertainty have slowed the development of new high-voltage energy infrastructure to bring additional carbon-free power to the grid. Undergrounding these long-distance lines would ease and shorten many parts of the painful process (as of publishing, tbd whether LK-99 is part of the solution here). Bedrock’s drilling tech could tunnel for transmission lines, and other startups like Petra are using superheated gas-spitting robots to drill tunnels 20 to 60 inches in diameter to bury utilities of various types.

Above: screenshot from a video showing Petra’s thermal tunneling robot at work

ARPA-E’s GOPHURRS program (truly an A++ acronym) is funding novel ways of undergrounding critical grid elements. Veir is a startup building transmission lines that can be automated to super-cool across their range as needed, and would work especially well in an underground setting. If the US doesn’t figure out ways to quickly deploy new transmission capacity at huge scale, as much as 80% of the 2030 emissions reductions potential in the IRA could go unrealized. Another portfolio company of ours, Blumen Systems*, is using LLMs to empower energy infrastructure and subsurface projects of all kinds to better slash through the often decade-plus permitting process.

Welcome to Caprock: Carbon Sequestration & Energy

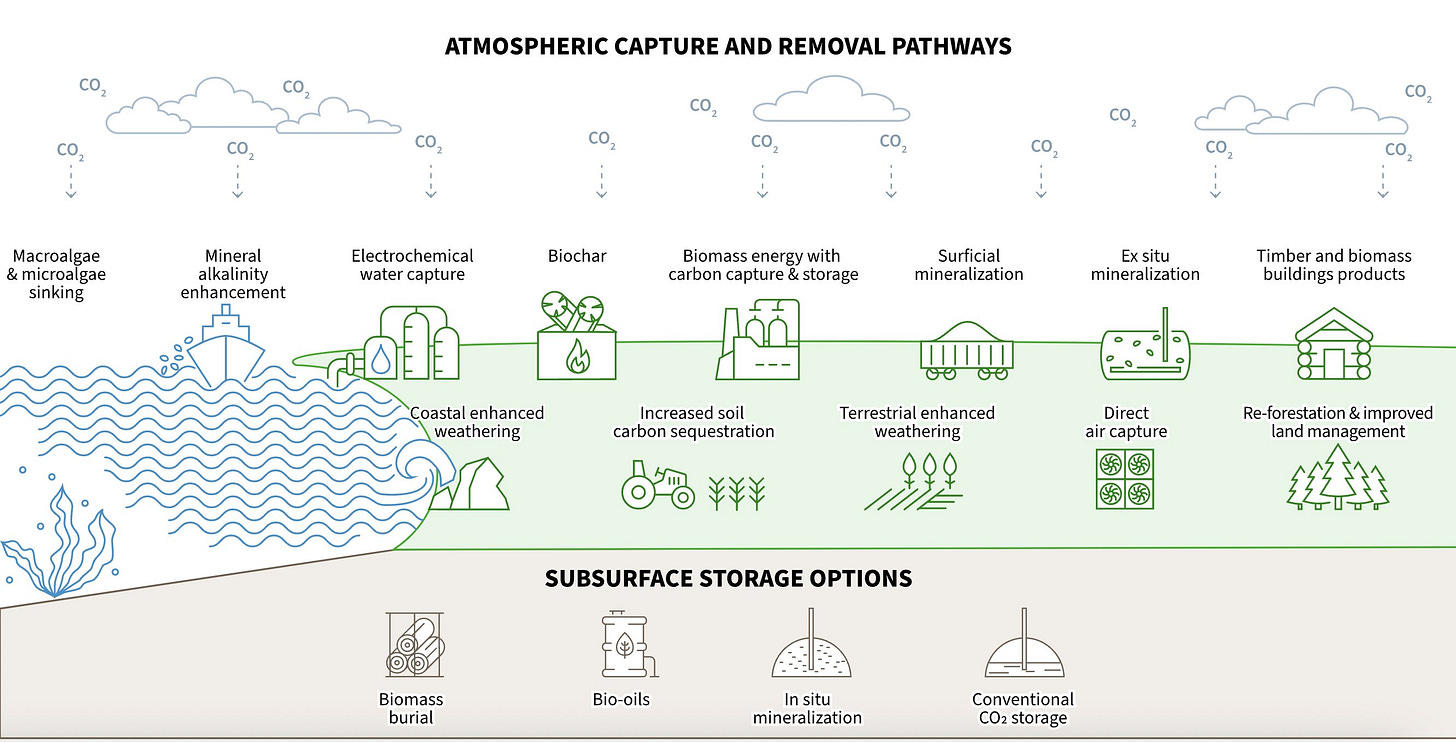

Carbon sequestration must skyrocket in volume if we are to hit any large-scale climate goals, and the subsurface will be critical here, too. Modeling and simulation for identifying, accessing and managing the right subsurface conditions for near-permanent storage of biomass and other sequestered carbon forms will be a key component of making the industry’s economics work.

Above: a graphic from Rocky Mountain Institute showing subsurface carbon capture and storage as the “final destination” for many pathways

Recent research suggests “migration-assisted trapping” via composite confining systems (using the subsurface’s natural makeup and porosity) can offer cost and process advantages over traditional O&G approaches that retain petrochemicals in a concentrated, mobile state. Vaulted Deep, a drilling tech spinout from O&G services company Advantek, recently raised VC money to sequester sludgy biomass on the cheap. Companies like Cella are matching carbon tonnage with the right subsurface conditions and MRV (monitoring, reporting, verification) approach to keep things buried for millennia.

Above: comparison of a conventional O&G seal to a composite confining system

Facing a similar set of technological challenges, underground energy storage is gaining momentum. CAES (compressed-air energy storage) can use retired oil and gas fields and aquifers to maintain pressurized gas underground to be discharged and repressurized as needed. Historically, this approach has not led to attractive energy density properties. Once again, improved control systems, sensor networks and automation can potentially make these approaches economical. Researchers are also testing hybrid approaches using thermal energy storage - one project is exploring the feasibility of dumping waste heat from data centers into abandoned coal mines underneath Edinburgh, UK to then be used in direct/district heating applications.

Above: a high-level schematic of a CAES system

Water (Fresh & Salty)

Fresh water is a big deal (duh). Our nation’s underground aquifers that feed vast portions of the world are being depleted and must be managed and restored. Monitoring, moving and replenishing those water sources is a monumental, many-faceted challenge – a better understanding of these systems is paramount.

Subsurface also means more than just continental rocks – oceans play so many critical roles in solving climate change. The ocean is already our planet’s largest heat sink. It’s been estimated that 90% of excess man-made warming energy has been absorbed by the oceans to-date. Now, we’re expecting to lean on them to sequester carbon and energy in the form of million-year bicarbonates, sunken biomass and more straight-up heat. There is already a huge wave of startups pursuing ocean CDR. We’ll need to plumb the depths for polymetallic nodules on the seafloor that contain critical minerals, lay undersea cables, install and operate offshore floating wind turbines, predict ocean currents for more efficient shipping – all of this will require massive amounts of novel design, automation, computing and data.

Scoot Science* uses AI and sensor data to build hyperlocal, highly-accurate forecasts of subsurface ocean conditions that aquaculture operators then use to run their farms and grow the industry. Typically, aquaculture operators can’t access financing, insurance, factoring or other slices of the capital stack due to the risk of sudden, extreme fish crop loss. An upwelling of cold water from the deep ocean (or a low-dissolved-oxygen event, or a harmful algae bloom, or a sea lice event, etc… you get the idea) can kill overnight dozens of millions of dollars worth of fish that took years to grow. Scoot’s tech sees the subsea weather days ahead and gives operators time to adapt, improving yields, growing access to capital and bringing more cheap, clean protein to the world. Their tech is also being applied as a solution for ocean CDR MRV (monitoring, reporting, verification).

Where do we go from here?

We go down.

We’re looking to back more entrepreneurs using all the wild new computing technology in the world to make subsurface industries better, faster, cheaper. If you know folks who are working on a problem that touches the subsurface, please reach out! (teddy at firststar dot vc or @teddypowday on twitter)